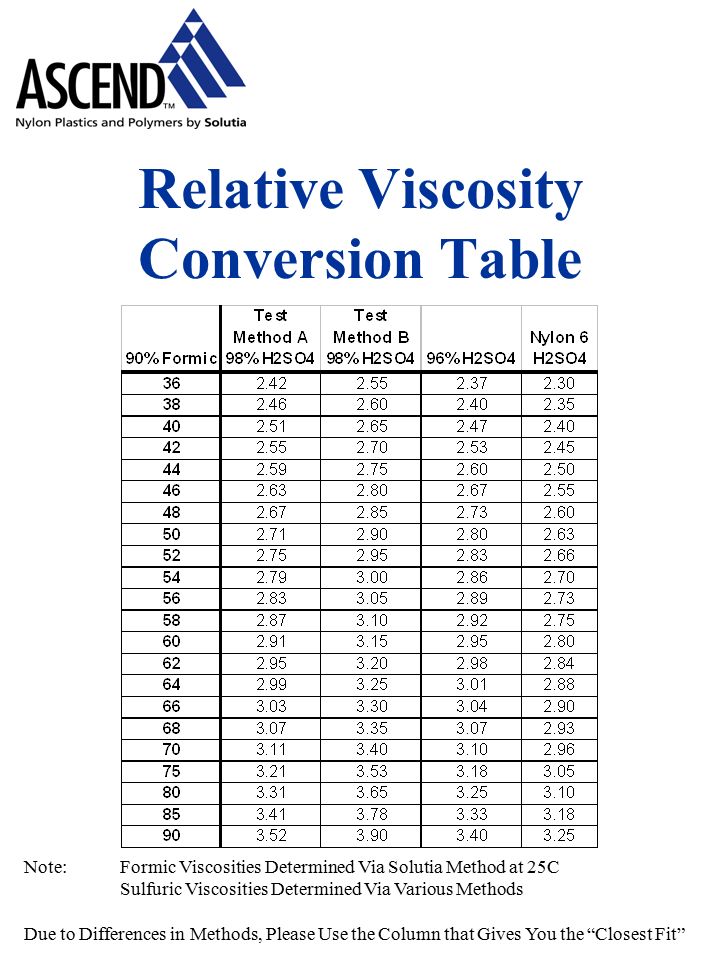

Nylon Relative Viscosity

2 Note: 1. For unreinforced materials, preferred mold temperature shall be about 30 °C (50 °F) lower than corresponding reinforced grades. 2.

2. HISTORY The development of nylon was started from 1927 by means of many researchers, notably among them W.H.Carothers and P.Schlack. The research activities preceding the manufacture of nylon yarn can be divided into the following categories:

Sigma-Aldrich offers Aldrich-429171, Nylon 6/6 for your research needs. Find product specific information including CAS, MSDS, protocols and references.

1. NYLON-MXD6 NYLON-MXD6 is one of the crystalline polyamide resins,Which is produced through polycondensation of meta-xylylene diamine (MXDA) with adipic acid under MGC’s own

Common Brand Names: Akulon K and F, Capron, Maranyl B, Nylacast, Orgamid, Ultramid B General Description: See also General Information under Nylon 6,6.

ACMI’s Catalog. ACMI offers a wide variety of coding and marking inks for an ever expanding list of applications. We have highlighted some of these ink categories and applications below.

2 Melt Rheology The effect of shear rate on viscosity at typical processing temperatures for the basic types of Hytrel is shown in Figure 1. The viscosity versus

1 MULTILAYER CONTAINERS FEATURING NANO-NYLON MXD6 BARRIER LAYERS WITH SUPERIOR PERFORMANCE AND CLARITY INTRODUCTION This presentation addresses the subject of PET bottles designed for applications requiring

Designation: D 4066 – 01a (Reapproved 2008) Standard Classification System for Nylon Injection and Extrusion Materials (PA)1 This standard is issued under the fixed designation D 4066; the number immediately following the …

Nylon Washers. New Process Fibre is unique in several ways. We believe that our ability to provide OEMs with cost-effective and innovative stamping solutions for nonmetallic parts is second-to-none.